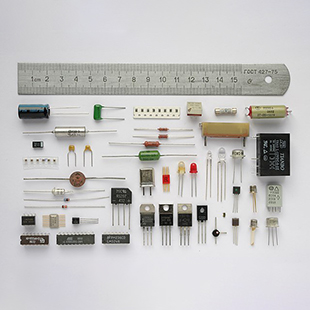

We list our usual material and technical specification of Flexible Circuits & flex printed circuits (FPC) in the below table. Also, you can view the facility tolerance of circuits.

If you would like some special material, tighter tolerance, or other requirements of flexible PCB (flex circuit board), you can Contact our staff directly, we are at your service at any time.

List of Flexible Circuit Manufacturing Capacity

| Parameter (mm) | Polyimide (PI) | PET | |

| Laminate Thickness | 0.025 / 0.050/ 0.125/ 0.175 | 0.025 / 0.050/ 0.075 | |

| Copper Foil | 0.012,0.018,0.035,0.070 | 0.035,0.070 | |

| Min Pattern width/Space | 0.075(3 mil) | 0.075(3 mil) | |

| Min. Drilled Hole Size | Non-Plated Thru | 0.25mm ( .010" ); Tolerance +/-.0386mm( .0015") | |

| Plated Thru | 0.1mm ( .010" ); Tolerance +/-.076mm( .0030") | ||

| Outlines Dimension | +/- 0.05mm | +/- 0.05mm | |

| Peeling Strength(180°Direction) | >1.2kgf / cm | >1.2kgf / cm | |

| Solder Hent Resistance | 280℃ / 10secs | 280℃ / 10secs | |

| Surface Treatment | Ni/Au | 2~5μm | 2~5μm |

| Au(Electro/Immersion) | 0.03 ~0.1μm | 0.03 ~0.1μm | |

| Sn/Pb (Lead Free) | 3~ 20μm | 3~ 20μm | |

| Sn-Cu Plating (Lead Free) | 3~ 5μm | 3~ 5μm | |

| Tin Plating (Pure Sn) | 5 ~ 8μm | 5 ~ 8μm | |

| Bending flexibility | Meet to IPC Criterion | ||

| Chemical Resistance |

Meet to IPC Criterion |

||

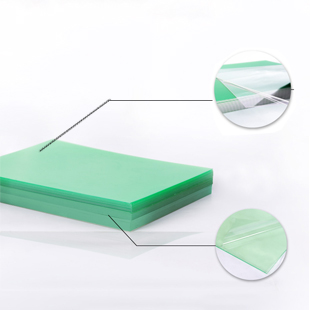

The most widely used Flexible Circuits & flex printed circuits (FPC) material today is manufactured by Dupont Corporation and is called "Kapton". This polyimide film based material is resistant to heat, has dimensional stability and a low dielectric constant of 3.6. The follows are basic Kapton materials:

Kapton FPC Materials

![]() Dupont Coverlay

Dupont Coverlay

![]() Dupont Copper Clad

Dupont Copper Clad

![]() Dupont Sheet Adhensive

Dupont Sheet Adhensive

There're also other companies whom make good Flexible Circuits & flex printed circuits board (FPCB) material, such as Rogers Corporation and is called "Rogers"

Roger FPC Materials

![]() Rogers-Liquid-PhotoImageable-Coverlay

Rogers-Liquid-PhotoImageable-Coverlay

![]() Rogers-RFlex1000

Rogers-RFlex1000

![]() Rogers-RFlex2005UL

Rogers-RFlex2005UL

EMC Shield Material

EMC Shielding Characteristics