Quality is vital! We have a very good warranty policy to guarantee against any potential imperfections of flexible circuits & flex printed circuits (FPC). The Quality Policy is established and structured to provide ISO 9001:2000-compliant quality management. Our quality management system is designed to provide satisfaction for our customers with defect-free products that conform to their requirements and are delivered on time.

Best FPC is committed to quality and the achievement of excellence throughout all company activities. All of our factories are strictly follow the operation procedures stipulated in ISO9001:2000 in respect to material purchasing, product manufacturing, testing, packing, marketing, etc. For example, during the production of FPC, all the garments must be checked piece by piece under strict on-site and final quality control. Click here to view our Test equipment.

Environmental Policy

Best FPC will build a perfectly environment-friendly and safe company that focused on mankind and will provide optimized plants and the best “Green Products” which can satisfy all employees, customers, and the community through continuous improvement action about environment and safety. All of our FPC are RoHS compliant, click here for more information about RoHS

How Do We Ensure the Quality and Reliability?

Raw Materials Guarantee. Pre-production Inspection. In Process Quality Control. Rigorous Testing And Inspection.

-

-

Reliable Raw Materials

More than 10 stable suppliers:

It is always known that the quality of raw materials determines the durability of the finished product.

Choosing the supplier of famous brand raw materials in PCB industry is the guarantee of stable quality of Best Technology. We only adopt premium materials to manufacture high-quality PCBs.

Our expertise regarding advanced material types and combinations allows us to offer our customers a cost-effective solution for almost any challenge.

-

-

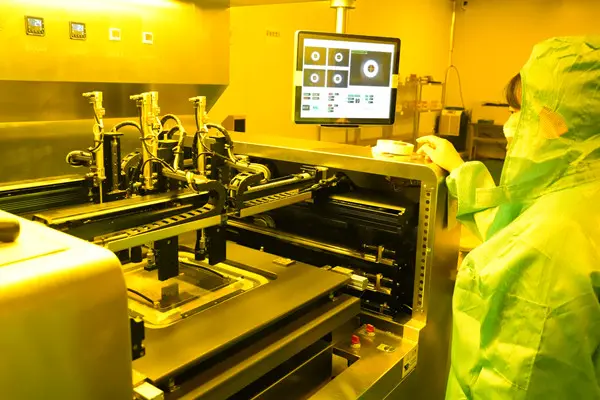

PCB Incoming Inspection

AOI inspection reduces error rate and improves efficiency:

We obtain all raw materials from selected suppliers known for their excellent quality.

Raw materials inspection is a vital step in our process.Here at Best Technology, no component or part before going to the warehouse without passing through a strict incoming inspection quality control process. Our PCB incoming inspection includes: size and appearance inspection, warping and distortion detection, solderability test, solder mask integrity test, Internal defect detection.

-

In-Process Quality Checking

Manual inspection is the last guarantee:

We have refined our quality management system over our 16 years in business to ensure predictable and repeatable outcomes.

We have incorporated the In-Process Quality Checking (IPQC) procedure in our production line. Any defective components or manufacturing errors are detected instantly and are eliminated.

All of boards will be 100% Inspection and E-test before delivery.

-